RTV COATING

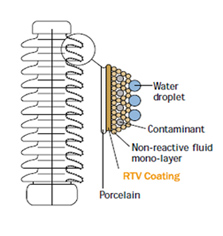

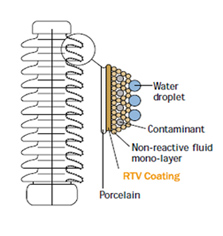

RTV Coating is a high voltage insulator coating which performs by virtue of its highly hydrophobic water repellent nature. It provides a virtually maintenance-free system to prevent leakage current, tracking and flashover on porcelain, glass, EPDM and liquid silicone rubber insulators. Because of its high degree of water repellency, contaminants cannot film out over the surface of

RTV Coating eliminating or reducing:

Regular insulator cleaning

Regular insulator cleaning

Periodic reapplication of grease

Periodic reapplication of grease

Replacement of components damaged by flashover

Replacement of components damaged by flashover

Insulator surfaces must be cleaned by high pressure water wash, crushed corn cob abrasive or by solvent for degreasing. All surfaces must be completely dry prior to application. Coating is easily accomplished by brush, spray or dipping to a final coating thickness of 380μ.

Non-reactive fluid from the coating micro-encapsulates contaminants to disrupt the continuous path which can lead to flashover. Rain and dew formation washes away contaminants under ordinary circumstances. Under heavy pollution conditions, periodic water washing may be required. Frequency of water washing will depend on severity of contamination.

BENEFITS

Virtually maintenance-free leakage current prevention for porcelain, glass, polymer and composite insulators

Virtually maintenance-free leakage current prevention for porcelain, glass, polymer and composite insulators

One-part, room temperature vulcanizing (RTV), elastomeric organosiloxane rubber

One-part, room temperature vulcanizing (RTV), elastomeric organosiloxane rubber

Simple application – brush or spray

Unparalleled resistance against UV, ozone, chemicals and normal weathering provides unsurpassed longevity

Simple application – brush or spray

Unparalleled resistance against UV, ozone, chemicals and normal weathering provides unsurpassed longevity

Proven effective in conditions from salt-fog to cement dust

Proven effective in conditions from salt-fog to cement dust

In-house coating is especially advantageous for projects using new insulators. A product ready to be installed is delivered and a hydrophobic insulator surface is assured from the very first day. De-energizing of the substations for frequent washing is no longer required and maintenance expenditure is reduced to a minimum compared to conventional porcelain insulator surfaces.

Upgrading existing substation equipment is possible by on-site coating. A trained and experienced coating team is sent to the de-energized substation. Our On-site coating is environmentally friendly – no dangerous or hazardous materials are used. At the moment the On-site coating service is offered in Europe only.

![]() Regular insulator cleaning

Regular insulator cleaning![]() Periodic reapplication of grease

Periodic reapplication of grease![]() Replacement of components damaged by flashover

Replacement of components damaged by flashover